Are you ready to discover the revolutionary material that is transforming the world of technology? Let me introduce you to LSR silicone, a game-changer in product quality and performance.

Click to find more about what is lsr silicone.

The Power of LSR Silicone

LSR silicone, also known as Liquid Silicone Rubber, is a versatile material with exceptional properties. It is created through a unique manufacturing process that involves injecting liquid silicone into molds and then curing it at high temperatures. This results in a durable, flexible, and heat-resistant material that can withstand extreme conditions.

One of the key advantages of LSR silicone is its ability to provide excellent electrical insulation. This makes it an ideal choice for electronic components such as connectors, cables, and insulators. Its high thermal stability ensures reliable performance even in demanding environments.

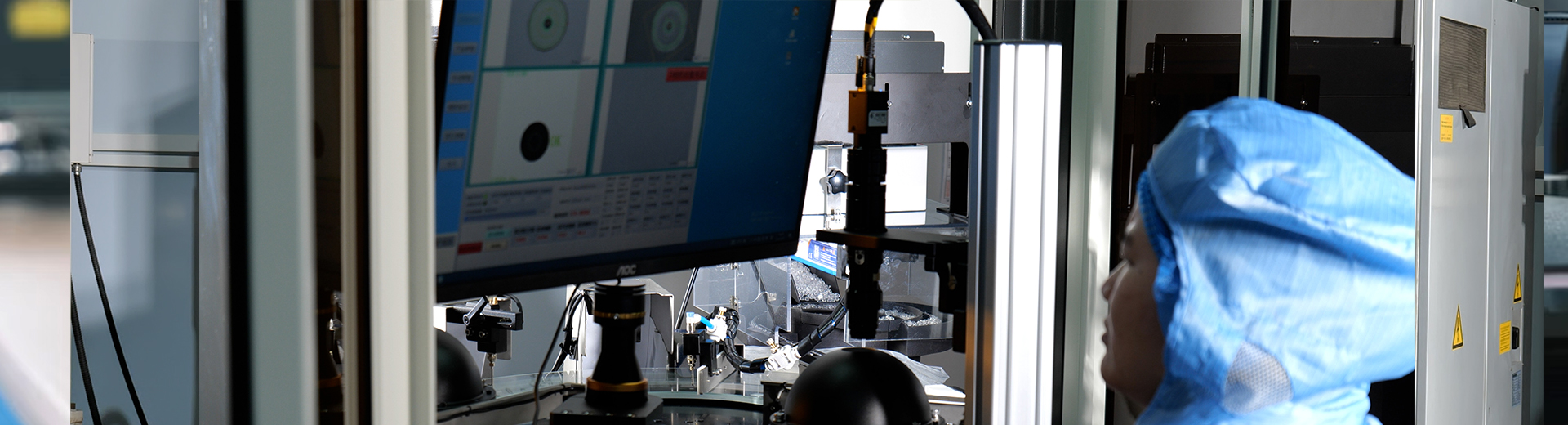

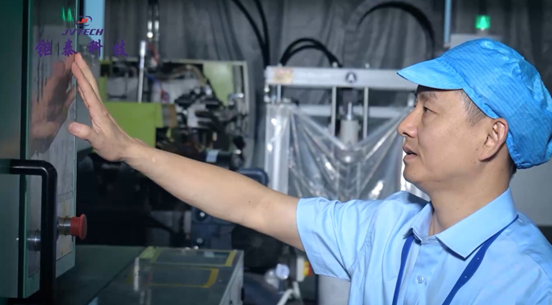

JVTECH: Harnessing the Potential

Innovation knows no bounds when it comes to JVTECH – a leading company harnessing the potential of LSR silicone. With their cutting-edge research and development efforts, they have unlocked new possibilities for this remarkable material.

JVTECH has successfully integrated LSR silicone into various products across industries like automotive, healthcare, electronics, and more. Their expertise lies not only in manufacturing but also in designing customized solutions tailored to meet specific requirements.

The Advantages of LSR Manufacturing

lsr manufacturing offers several advantages over traditional methods. Firstly, its liquid form allows for intricate designs with precise details that are difficult to achieve using other materials or processes. This opens up endless opportunities for creating complex shapes and structures.

Secondly, due to its low viscosity nature during injection molding process,LSR silicone exhibits minimal shrinkage, resulting in consistent dimensions and improved product quality. This ensures that every product manufactured with LSR silicone meets the highest standards of performance and reliability.

Furthermore, LSR manufacturing enables faster production cycles, reducing time-to-market for new products. Its ability to be easily automated also enhances efficiency and cost-effectiveness in large-scale manufacturing operations.

In Conclusion

LSR silicone is a game-changer in the world of technology, offering unparalleled product quality and performance. With its exceptional properties and versatility, it has become an indispensable material across various industries. Thanks to companies like JVTECH pushing the boundaries of innovation, we can expect even more exciting advancements in LSR silicone applications in the future.