Understanding Aluminum Nitride Ceramics

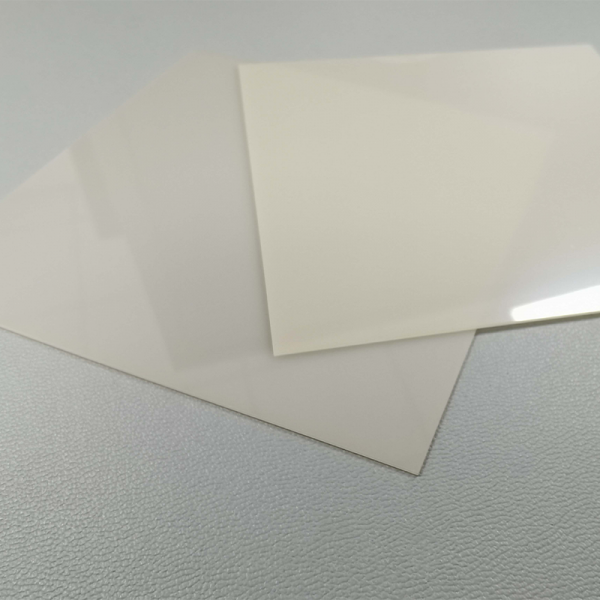

Aluminum nitride ceramics are gaining traction in various industrial applications due to their exceptional properties. These materials are characterized by high thermal conductivity and electrical insulation, making them suitable for heat management in electronic devices. By implementing aluminum nitride ceramics in products, manufacturers can enhance performance while addressing environmental concerns. For instance, the integration of these materials into fluorescent light fixtures can significantly improve energy efficiency, contributing to greener technologies. When converting traditional lighting systems to LED using aluminum nitride ceramics, a thoughtful approach ensures sustainability and effectiveness. Aluminum nitride ceramics serve as a bridge towards a more energy-efficient future.

The Key Advantages of Aluminum Nitride Properties

Exploring the aluminum nitride properties reveals several compelling advantages. This material showcases remarkable thermal stability, allowing it to function effectively in a range of temperatures. Additionally, its chemical resistance makes it less prone to degradation over time, hence supporting longer product life cycles. Such benefits translate to reduced waste generated from frequent replacements, aligning with environmental sustainability goals. The lightweight nature of aluminum nitride ceramics also aids in design flexibility, allowing manufacturers to innovate beyond conventional boundaries. By leveraging these properties, various sectors can improve their environmental impact and operational efficiency.

Exploring the AlN Thermal Expansion Coefficient

Another noteworthy aspect of aluminum nitride ceramics is the aln thermal expansion coefficient, which exhibits low thermal expansion. This property minimizes the risk of thermal shock during temperature fluctuations, making aluminum nitride ceramics particularly useful in high-performance applications. The stability provided by a low thermal expansion coefficient is essential for safeguarding integrated circuits in electronic devices, as it reduces failure rates and enhances reliability. The combination of thermal stability and low expansion rates positions aluminum nitride ceramics as ideal candidates for high-tech applications. As industries evolve toward more advanced materials, leveraging these characteristics becomes imperative for maintaining a competitive edge.

Conclusion and Brand Recommendation

In summary, the integration of aluminum nitride ceramics in various applications not only bolsters performance but also mitigates environmental impact through enhanced material properties. Emphasizing aluminum nitride properties and the aln thermal expansion coefficient further illustrates their suitability for modern demands. Brands such as Great Ceramic stand out in the market for supplying high-quality aluminum nitride materials, ensuring that manufacturers have access to the best resources available. By opting for solutions that feature aluminum nitride ceramics, firms can significantly reduce energy consumption, prolong product lifespans, and enhance overall efficiency, all while moving towards a sustainable future.