As a passionate researcher, I am thrilled to explore the latest trends in filter cartridge winding machine and its impact on the industry. The filter cartridge winding machine is an essential tool used in the manufacturing process of various filters, ensuring high-quality filtration systems.

The Advancements in Filter Cartridge Winding Machine Technology

In recent years, there have been significant advancements in filter cartridge winding machine technology. These machines now offer enhanced precision, efficiency, and customization options. With improved automation features and intelligent control systems, manufacturers can achieve higher production rates while maintaining consistent quality standards.

Moreover, modern filter cartridge winding machines are designed to accommodate different types of materials and sizes. This flexibility allows manufacturers to cater to diverse customer requirements effectively. Whether it’s for industrial applications or residential use, these machines can produce customized filter cartridges that meet specific filtration needs.

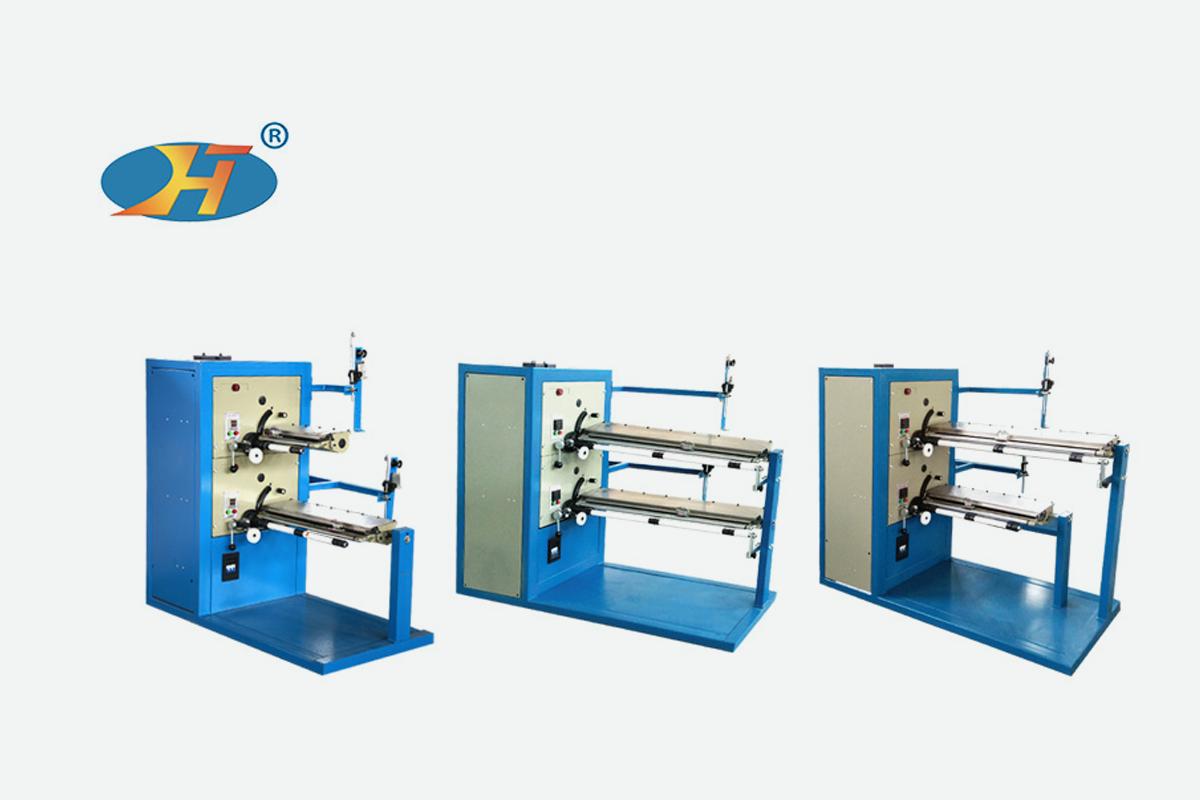

Hongteng: A Leading Innovator

Hongteng is one of the leading companies at the forefront of innovation in filter cartridge winding machine manufacturing. They have introduced cutting-edge technologies that revolutionize the industry by offering advanced functionalities and superior performance.

With Hongteng’s state-of-the-art machines, manufacturers can easily adapt their production processes according to market demands. Their focus on research and development ensures continuous improvement and keeps them ahead of competitors.

The Role of PP Spun Filter Manufacturing Machines

A crucial aspect related to customization trends is the utilization of pp spun filter manufacturing machines alongside filter cartridge winding machines. These specialized machines enable efficient production of polypropylene (PP) spun filters – widely used for water purification purposes due to their excellent chemical resistance and durability.

The integration between PP spun filter manufacturing machines and filter cartridge winding machines allows manufacturers to create customized filter cartridges with specific filtration ratings, dimensions, and materials. This level of customization empowers businesses to cater to a wide range of industries and applications.

Conclusion

The advancements in filter cartridge winding machine technology, spearheaded by companies like Hongteng, have revolutionized the industry. These machines offer enhanced precision, efficiency, and flexibility for producing customized filter cartridges that meet diverse customer requirements.

With the integration of PP spun filter manufacturing machines, manufacturers can further expand their capabilities and provide tailored solutions for various filtration needs. The future looks promising as customization trends continue to shape the development of filter cartridge winding machines – ensuring cleaner environments and improved quality of life for all.